MANUFACTURING PROCESS

QUALITY

We at MEKATEK are committed to providing the utmost guarantees and quality in terms of our service. Our value proposal is defined by rigour and therefore stringent control is one of the keys to what we offer the customer.

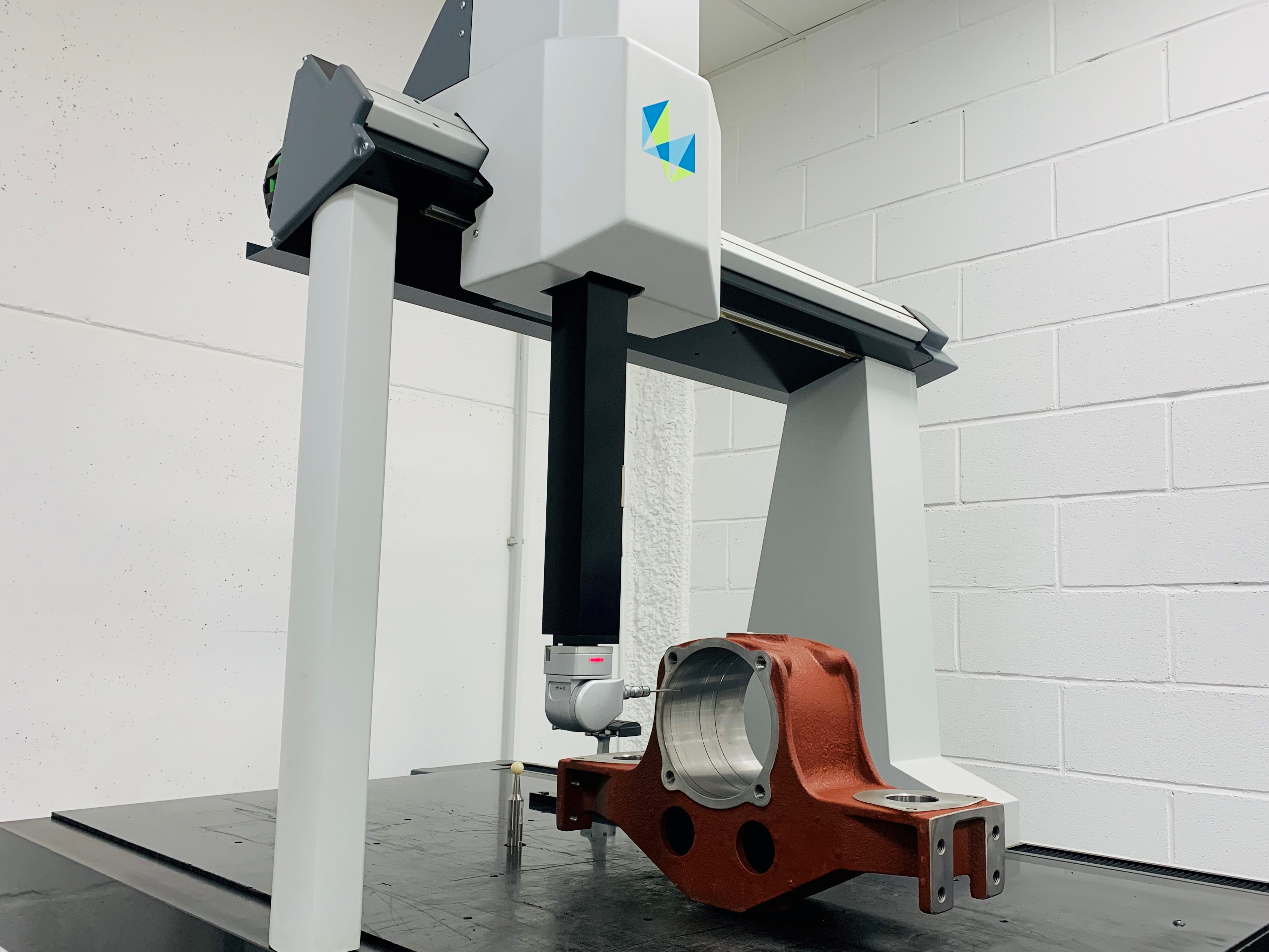

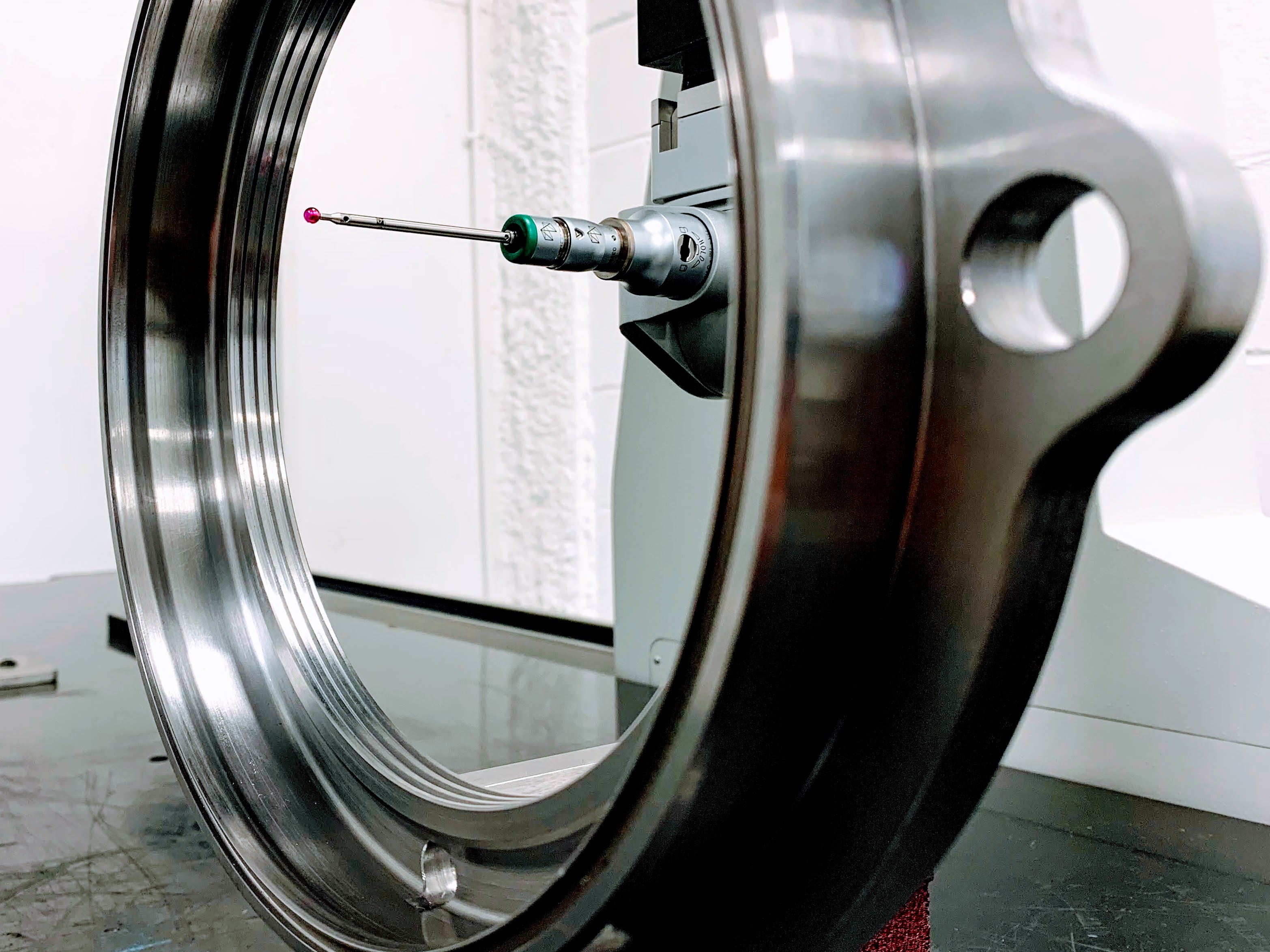

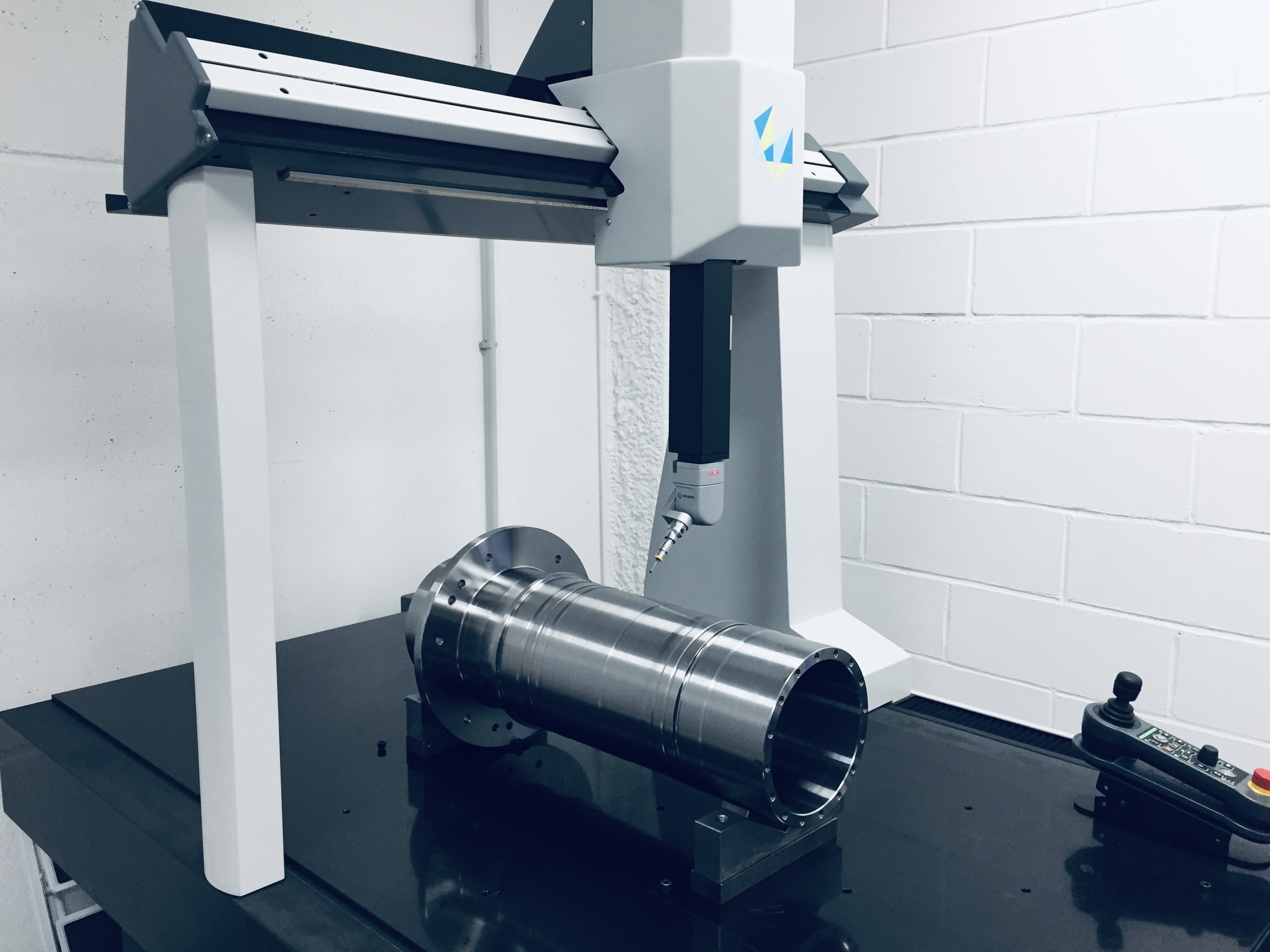

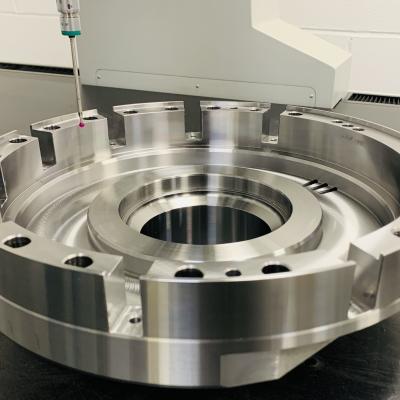

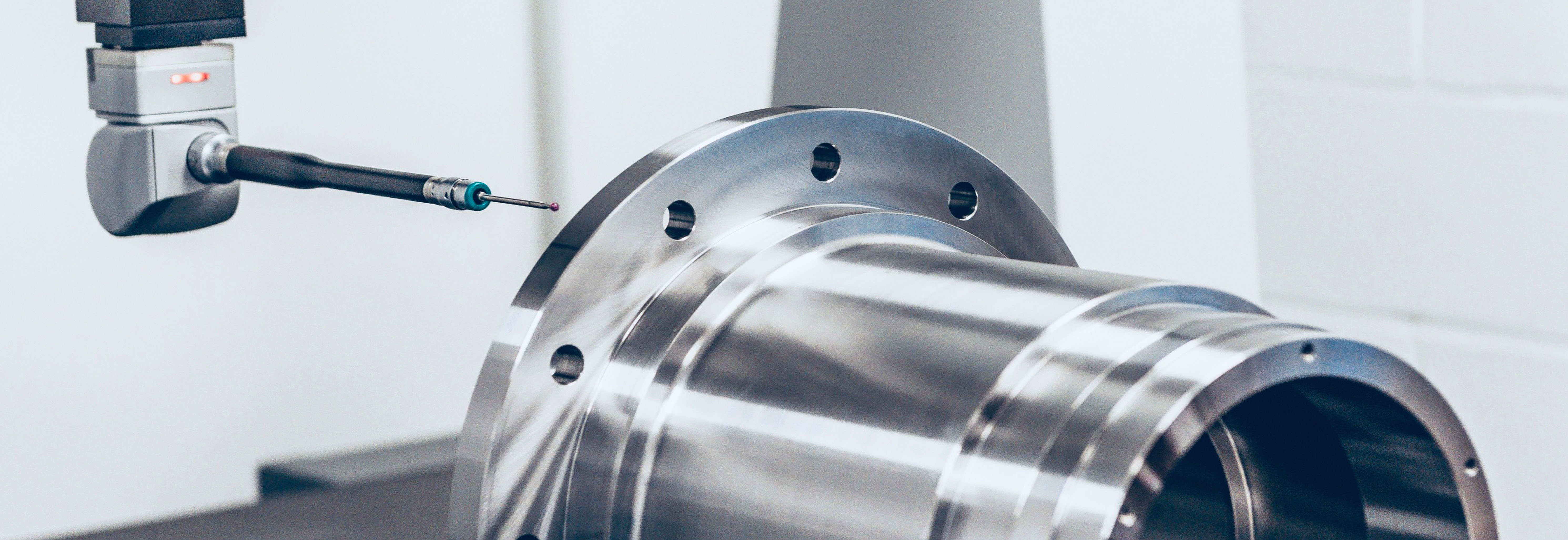

THREE-DIMENSIONAL MEASURING SERVICES

We have experience and expertise in measuring strategies, whereby we also provide the sector with a three-dimensional measuring service that is reliable, precise and affords great flexibility.

To this end, we have an 08.12.06 model HEXAGON Pioneer coordinate measuring machine at our disposal, with maximum admissible error of MPEe = 2.9+4.0 L/1000.

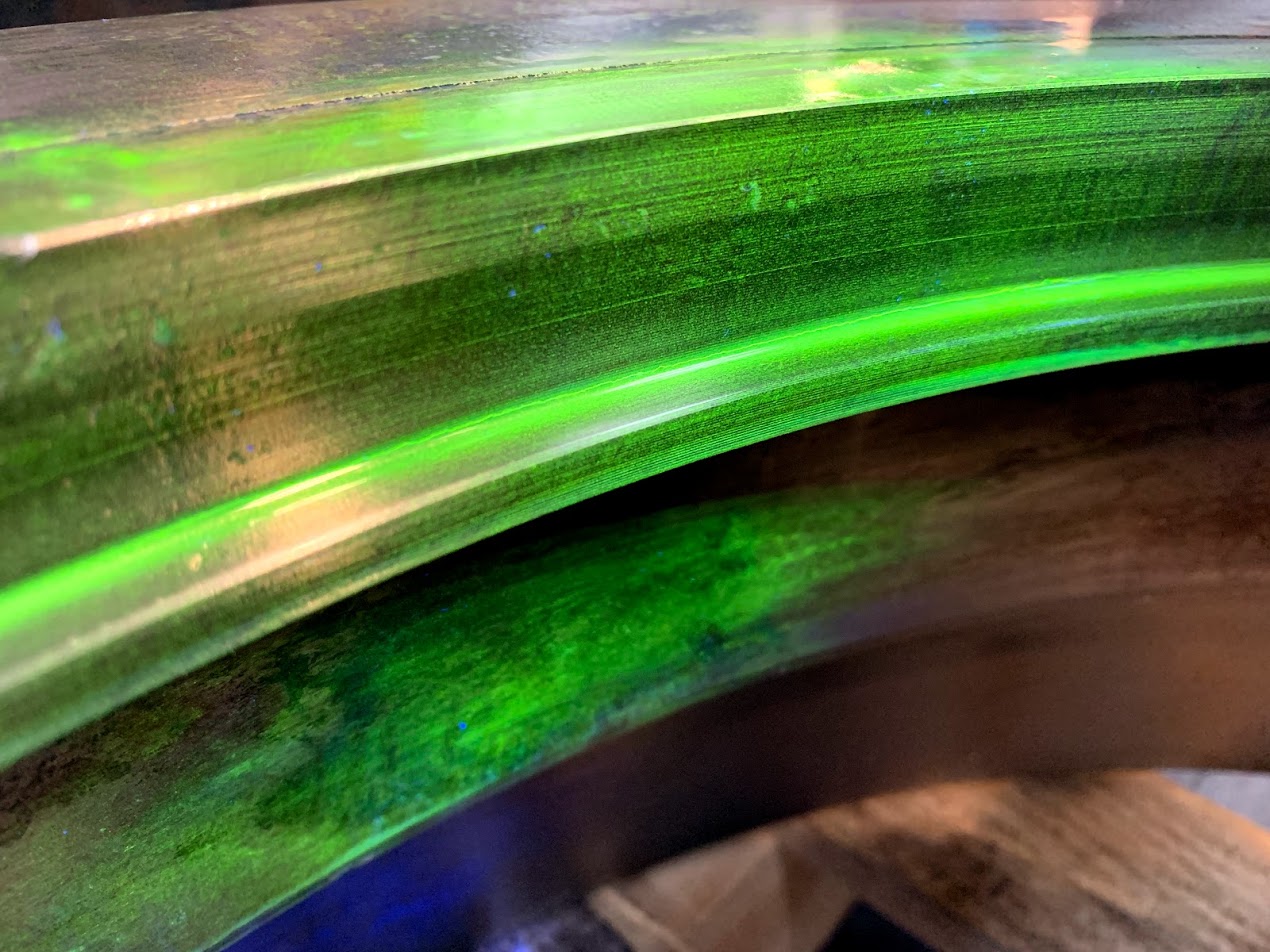

NON-DESTRUCTIVE TESTS

Quality control of the material is essential for many our customers. We undertake penetrant liquid and magnetic particle tests mainly on cast, forged and mechano-welded parts, with a view to verifying the homogeneity and continuity of the materials.

We also have equipment at our disposal to control the hardness, roughness and thickness of the chrome layer in order to verify both the physical and mechanical properties of manufactured components.